Key Features of Micro Industries' Ribbon Blenders:

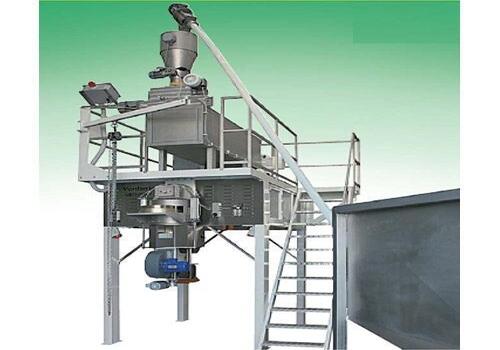

Capacity Versatility: We offer Ribbon Blenders in a wide range of capacities, from small laboratory-scale models (25 kg) to large-scale industrial units (7 KL). This allows us to cater to the specific production requirements of various businesses.

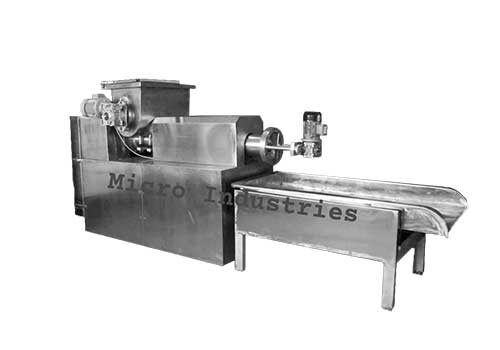

Material Options: We understand the importance of material compatibility in food-grade and other sensitive applications. Our blenders are available in mild steel (MS) or high-quality stainless steel (SS 304 and SS 316) construction, ensuring optimal hygiene and meeting industry standards.

Customizable Design: We recognize that every mixing application is unique. Our team can work with you to customize your Ribbon Blender with features like:

Variable Speed Drives: For precise control over mixing intensity and processing time.

Heating/Cooling Jackets: To maintain consistent product temperature during mixing.

Dust Tight Construction: For applications requiring a clean and controlled environment.

Discharge Options: Including butterfly valves, slide gates, and bottom discharge configurations for efficient product unloading.

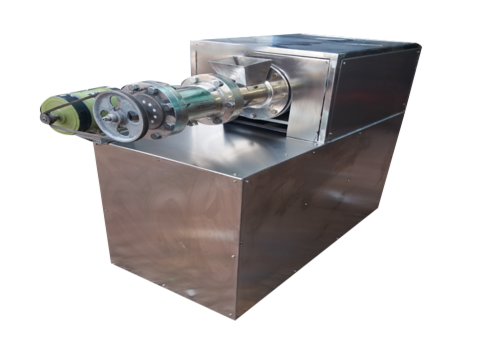

Durable Construction: Our blenders are built to last, using robust materials and high-quality engineering practices.

User-Friendly Operation: Our blenders are designed for ease of use, with intuitive controls and simple cleaning procedures.

Benefits of Using a Micro Industries Ribbon Blender:

High-Quality Blending: Ensures consistent and homogeneous mixtures, critical for maintaining product quality and performance.

Gentle Mixing: The unique ribbon design minimizes product degradation, making it ideal for delicate ingredients.

Efficient Mixing: Achieves a uniform mix in a short time, maximizing production efficiency and throughput.

Versatility: Suitable for a wide range of dry bulk solids, powders, and granules.

Durability: Built to withstand demanding industrial environments.

Customization: Tailored to meet your specific needs and applications.

Reduced Labor Costs: Automated operation minimizes manual intervention.

Improved Safety: Dust-tight options create a cleaner and safer working environment.

Applications of Micro Industries' Ribbon Blenders:

Micro Industries' Ribbon Blenders find application in a diverse range of industries, including:

Food Processing: Mixing dry ingredients for various food products like bakery mixes, spices, coffee, and pharmaceuticals.

Chemical Industry: Blending pigments, dyes, and other dry chemical components.

Plastics Industry: Mixing plastic granules, resins, and additives.

Cosmetics Industry: Combining dry cosmetic ingredients.

Pharmaceutical Industry: Mixing pharmaceutical powders and excipients.

Nutraceutical Industry: Combining dry ingredients for dietary supplements.

Feed Industry: Mixing animal feed components.

Frequently Asked Questions

What is the minimum capacity of your Ribbon Blenders in Delhi?

Our smallest Ribbon Blenders have a capacity of 25 kg, ideal for laboratory or pilot-scale mixing applications.

What materials can your Blenders handle?

We offer MS and SS construction to accommodate various material needs. For food-grade applications and those requiring a high degree of hygiene, we recommend our SS models.

How easy are your Blenders to clean?

Our Ribbon Blenders are designed for user-friendly cleaning. The smooth, polished surfaces minimize material build-up, and the easily accessible trough allows for thorough cleaning.

What kind of warranty do you offer on your Blenders?

We offer a competitive warranty on our Ribbon Blenders, ensuring your peace of mind. Please contact our sales team for specific warranty details.

Do you provide installation and after-sales support?

Yes, we offer comprehensive installation and after-sales support services. Our team of experienced engineers can assist with installation, commissioning, and provide ongoing maintenance support to ensure your Ribbon Blender operates at optimal performance.

.jpg)

.jpg)