The Micro Industries Soya Chunks Making Machine: A Game Changer

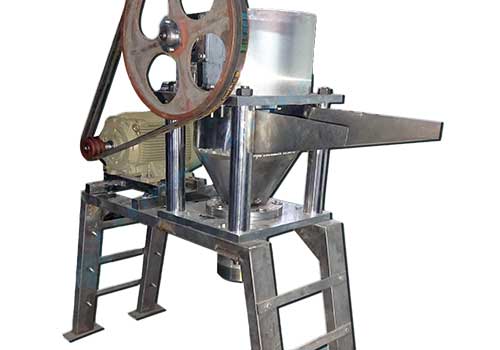

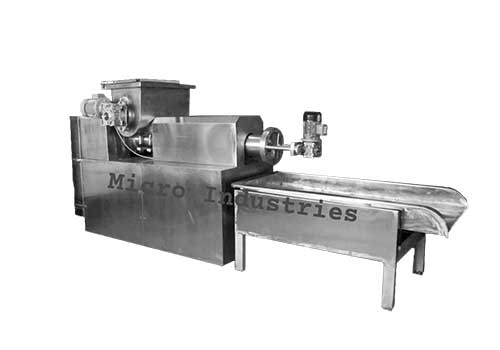

Micro Industries' Soya Chunks Making Machine streamlines the production process, transforming defatted soy flour or soy protein isolate into delectable and texturized soya chunks. Here's a breakdown of its key features:

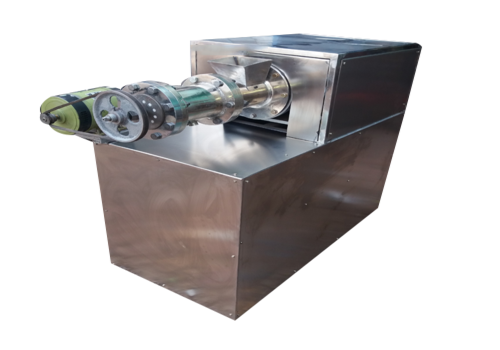

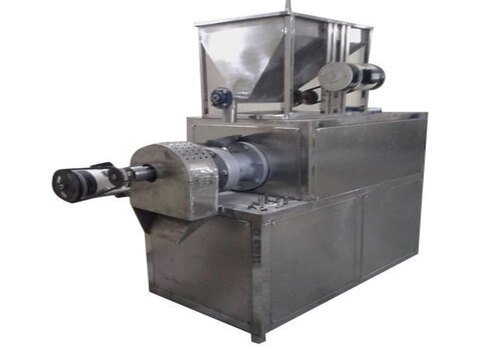

Efficient Extrusion Process: The machine utilizes an extruder with a specifically designed screw to effectively cook, texturize, and shape the soya material.

Capacity Options: Micro Industries offers machines with varying production capacities to cater to diverse business needs, from small-scale startups to large-scale manufacturers.

Control Panel: A user-friendly control panel allows for precise control over parameters like temperature, pressure, and extrusion speed, ensuring consistent product quality.

Durable Construction: Built with high-grade materials, the machine is designed to withstand the rigors of continuous operation.

Easy Maintenance: Micro Industries prioritizes user-friendliness. Their machines are designed for easy cleaning and maintenance, minimizing downtime.

Benefits of Choosing Micro Industries

There are numerous advantages to partnering with Micro Industries for your Soya Chunks Making Machine needs:

Enhanced Productivity: Their machines are known for their speed and efficiency, enabling you to meet growing production demands.

Superior Soya Chunks: The machines produce high-quality, consistent soya chunks with a desirable texture and bite.

Reduced Operational Costs: Micro Industries' machines optimize energy consumption, minimizing production costs.

Scalability: Their machines offer the flexibility to scale up production as your business grows.

Exceptional Customer Service: From pre-sales consultation to after-sales support, Micro Industries prioritizes customer satisfaction.

Beyond the Machine: A Complete Solution Provider

Micro Industries understands that a successful soya chunks operation goes beyond just the machine. They offer additional services to ensure a smooth production process:

Installation and Commissioning: Their experienced technicians will expertly install and commission your machine, ensuring it operates at peak performance.

Training: Micro Industries provides comprehensive training to your staff on the safe and efficient operation of the machine.

Technical Support: They have a dedicated team available to address any technical issues or questions you may have.

Frequently Asked Questions

What are the raw materials required to produce soya chunks in Mumbai?

Defatted soy flour or soy protein isolate are the primary raw materials used in soya chunks production. Additionally, water, oil, and other ingredients may be included depending on the desired flavor and texture.

What capacity options do your Soya Chunks Making Machines offer?

Micro Industries offers a variety of machine capacities, typically ranging from 50 kg/hr to 1000 kg/hr or more. They can work with you to determine the most suitable capacity for your specific production needs.

Can your machines produce different shapes and sizes of soya chunks?

Yes, by adjusting the die configurations within the extruder, Micro Industries' machines can produce soya chunks in various shapes and sizes to cater to different market preferences.

What is the estimated power consumption of your machines?

The exact power consumption will depend on the specific machine capacity and model. Micro Industries can provide detailed information on power requirements during the consultation process.

How do I ensure the proper maintenance of my Soya Chunks Making Machine?

Micro Industries provides a comprehensive user manual with detailed cleaning and maintenance instructions.

.jpg)